PRODUCTS

316 Stainless Steel Plate

Category:

Stainless Steel Plate

keywords :

Stainless Steel Plate

Product Introduction

316 Stainless Steel Plate Description

Grade 316 stainless steel is an austenitic form of stainless steel with a molybdenum content of 2-3%. The addition of molybdenum makes the metal more resistant to pitting and corrosion and improves its resistance to exposure to high temperatures. This grade of stainless steel is particularly effective when used in acidic environments. With this metal, corrosion caused by acetic acid, hydrochloric acid and other forms of acid can be prevented.

Product Parameters

|

Product Name |

316 Stainless Steel Plate |

|

Type |

Plate |

|

Thickness |

0.3mm-200mm |

|

Length |

2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

|

Width |

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

Surface |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Scope of Application |

Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

|

Certificate |

ISO, SGS, BV, etc. |

|

Production Technology |

Hot Rolling, Cold Rolling |

|

Edge Processing |

Edging, Trimming |

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

Mo |

|

≤ 0.03 |

≤ 0.75 |

≤ 2.0 |

16.0~18.0 |

10.0~14.0 |

≤ 0.03 |

≤ 0.045 |

2.0~3.0 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥480 |

≥177 |

≥ 40 |

≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.99 |

193 |

16.0 |

16.2 |

74 |

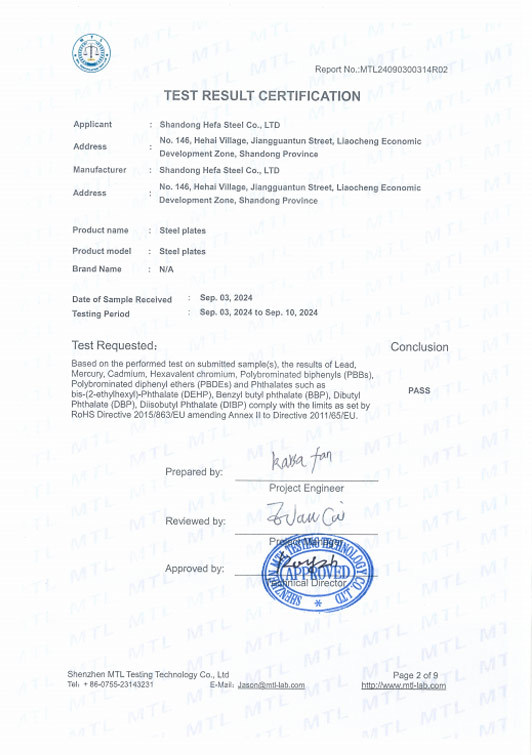

Surface Selection

| Name | Surface | Features | Use |

| Original Surface | NO.1 | Silver white |

Industrial tanks, chemical industry equipment, etc., thicker by the mm-10.0mm of 3.0. Uses that do not require a surface gloss |

| Matte | |||

| Nlunt Surface | 2D | Slightly shiny silvery white |

Used for deep drawing processing, such as automobile components, water pipes, etc. General materials, deep drawing materials |

| Fog Surface | 2B | Silver white with better gloss and flatness than 2D surface 0.39 micron roughness |

Such as tableware, building materials, etc. After surface treatment to improve mechanical properties, almost all applications are satisfied. |

| Frosted Surface | NO.3 | Has a good gloss, with discontinuous rough |

Used for building interior and exterior decoration materials, electrical products and kitchen equipment. |

| Frosted Surface | NO.4 | Has a better gloss, with discontinuous rough, stripes than NO. 3 fine |

Used for baths, building interior and exterior decoration materials, electrical products, kitchen equipment and food equipment. |

| Frosted Surface | NO.240 | Has a better gloss, with discontinuous rough, stripes than NO. 4 fine |

Used for bathroom, building interior and exterior decoration materials, electrical products, kitchen equipment and food equipment. |

| Frosted Surface | NO.320 | Has a good gloss, with discontinuous rough | Building Materials, Kitchenware |

| Frosted Surface | NO.400 | Has a good gloss, with discontinuous rough | Building materials, kitchen utensils, food equipment, etc. |

| Brushed Surface | HL | Silver gray with hairline stripes on the 2D or 2B product with the appropriate particle size abrasive material polished to make the surface continuous grinding pattern | Mainly used in architectural decoration, elevators, building doors, panels, etc. |

| Bright Surface | BA | Excellent surface gloss with high reflectivity | Used for home appliances, mirrors, kitchen equipment, decorative materials, etc. |

| Mirror | 6K | Not much worse than a mirror. | Mirror, trim panel |

| Mirror | 8K | Like a mirror. | Mirror, trim panel |

|

No |

China | Japan | USA | South Korea | Germany | India | Australia | Taiwan, China | |

|

|

GB |

JIS |

ASTM |

UNS |

KS |

DIN |

BIS |

AS |

CNS |

| Austenitic stainless steel | |||||||||

|

1 |

12Cr17Mn6Ni5N |

SUS201 |

201 |

S20100 |

STS201 |

1.4372 |

10Cr17Mn6Ni4N20 |

201-2 |

201 |

|

2 |

12Cr18Mn9Ni5N |

SUS202 |

202 |

S20200 |

STS202 |

1.4373 |

- |

- |

202 |

|

3 |

12Cr17Ni7 |

SUS301 |

301 |

S20200 |

STS301 |

1.4319 |

10Cr17Ni7 |

301 |

301 |

|

4 |

06Cr19Ni10 |

SUS304 |

304 |

S30400 |

STS304 |

1.4301 |

07Cr18Ni9 |

304 |

304 |

|

5 |

022Cr19Ni10 |

SUS304L |

304L |

S30403 |

STS304L |

1.4306 |

02Cr18Ni11 |

304L |

304L |

|

6 |

06Cr19Ni10N |

SUS304N1 |

304N |

S30451 |

STS304N1 |

1.4315 |

- |

304N1 |

304N1 |

|

7 |

06Cr19Ni9NbN |

SUS304N2 |

XM21 |

S30452 |

STS304N2 |

- |

- |

304N2 |

304N2 |

|

8 |

022Cr19Ni10N |

SUS304LN |

304LN |

S30453 |

STS304LN |

- |

- |

304LN |

304LN |

|

9 |

10Cr18Ni12 |

SUS305 |

305 |

S30500 |

STS305 |

1.4303 |

- |

305 |

305 |

|

10 |

06Cr23Ni13 |

SUS309S |

309S |

S30908 |

STS309S |

1.4833 |

- |

309S |

309S |

|

11 |

06Cr25Ni20 |

SUS310S |

310S |

S31008 |

STS310S |

1.4845 |

- |

310S |

310S |

|

12 |

06Cr17Ni12Mo2 |

SUS316 |

316 |

S31600 |

STS316 |

1.4401 |

04Cr17Ni12Mo2 |

316 |

316 |

|

13 |

06Cr17Ni12Mo2Ti |

SUS316Ti |

316Ti |

S31635 |

- |

1.4571 |

04Cr17Ni12MoTi20 |

316Ti |

316Ti |

|

14 |

022Cr17Ni12Mo2 |

SUS316L |

316L |

S31603 |

STS316L |

1.4404 |

~02Cr17Ni12Mo2 |

316L |

316L |

|

15 |

06Cr17Ni12Mo2N |

SUS316N |

316N |

S31651 |

STS316N |

- |

- |

316N |

316N |

|

16 |

022Cr17Ni13Mo2N |

SUS316LN |

316LN |

S31653 |

STS316LN |

1.4429 |

- |

316LN |

316LN |

|

17 |

06Cr18Ni12Mo2Cu2 |

SUS316J1 |

- |

- |

STS316J1 |

- |

- |

316J1 |

316J1 |

|

18 |

022Cr18Ni14Mo2Cu2 |

SUS316J1L |

- |

- |

STS316J1L |

- |

- |

- |

316J1L |

|

19 |

06Cr19Ni13Mo3 |

SUS317 |

317 |

S31700 |

STS317 |

- |

- |

317 |

317 |

|

20 |

022Cr19Ni13Mo3 |

SUS317L |

317L |

S31703 |

STS317L |

1.4438 |

- |

317L |

317L |

|

21 |

06Cr18Ni11Ti S |

SUS321 |

321 |

S32100 |

STS321 |

1.4541 |

04Cr18Ni10Ti20 |

321 |

321 |

|

22 |

06Cr18Ni11Nb |

SUS347 |

347 |

S34700 |

STS347 |

1.4550 |

04Cr18Ni10Nb40 |

347 |

347 |

| Duplex stainless steel | |||||||||

|

1 |

- |

SUS329J1 |

329 |

S32900 |

STS329J1 |

1.4477 |

- |

329J1 |

- |

|

2 |

022Cr23Ni5Mo3N |

- |

S32205 |

F60 |

- |

1.4462 |

- |

2205 |

2205 |

|

3 |

022Cr25Ni7Mo4N |

- |

S32750 |

F53 |

- |

1.4410 |

- |

2507 |

2507 |

| Ferritic stainless steel | |||||||||

|

1 |

06Crl3Al |

SUS405 |

405 |

S40500 |

STS405 |

1.4002 |

04Cr13 |

405 |

405 |

|

2 |

022Cr11Ti |

SUH409 |

409 |

S40900 |

STS409 |

1.4512 |

- |

409L |

409L |

|

3 |

022Cr12 |

SUS410L |

- |

- |

STS410L |

- |

- |

410L |

410L |

|

4 |

10Cr17 |

SUS430 |

430 |

S43000 |

STS430 |

1.4016 |

05Cr17 |

430 |

430 |

|

5 |

10Cr17Mo |

SUS434 |

434 |

S43400 |

STS434 |

1.4113 |

- |

434 |

434 |

|

6 |

022Cr18NbTi |

- |

- |

S43940 |

- |

1.4509 |

- |

439 |

439 |

|

7 |

019Cr19Mo2NbTi |

SUS444 |

444 |

S44400 |

STS444 |

1.4521 |

- |

444 |

444 |

| Martensitic stainless steel | |||||||||

|

1 |

12Cr12 |

SUS403 |

403 |

S40300 |

STS403 |

- |

- |

403 |

403 |

|

2 |

12Cr13 |

SUS410 |

410 |

S41000 |

STS410 |

1.4006 |

12Cr13 |

410 |

410 |

|

3 |

20Cr13 |

SUS420J1 |

410 |

S42000 |

STS420J1 |

1.4021 |

20Cr13 |

420 |

420J1 |

|

4 |

30Cr13 |

SUS420J2 |

- |

- |

STS420J2 |

1.4028 |

30 Cr13 |

420J2 |

420J2 |

|

5 |

68Cr17 |

SUS440A |

440A |

S44002 |

STS440A |

- |

- |

440A |

440A |

Packing and delivery

The products have been exported to more than 100 countries and regions, including Turkey, Russia, Saudi Arabia, UAE, Iran, Kuwait, Poland, Philippines, Indonesia, Kazakhstan, Brazil, Mexico, Egypt, Nigeria, South Africa, Australia, etc.

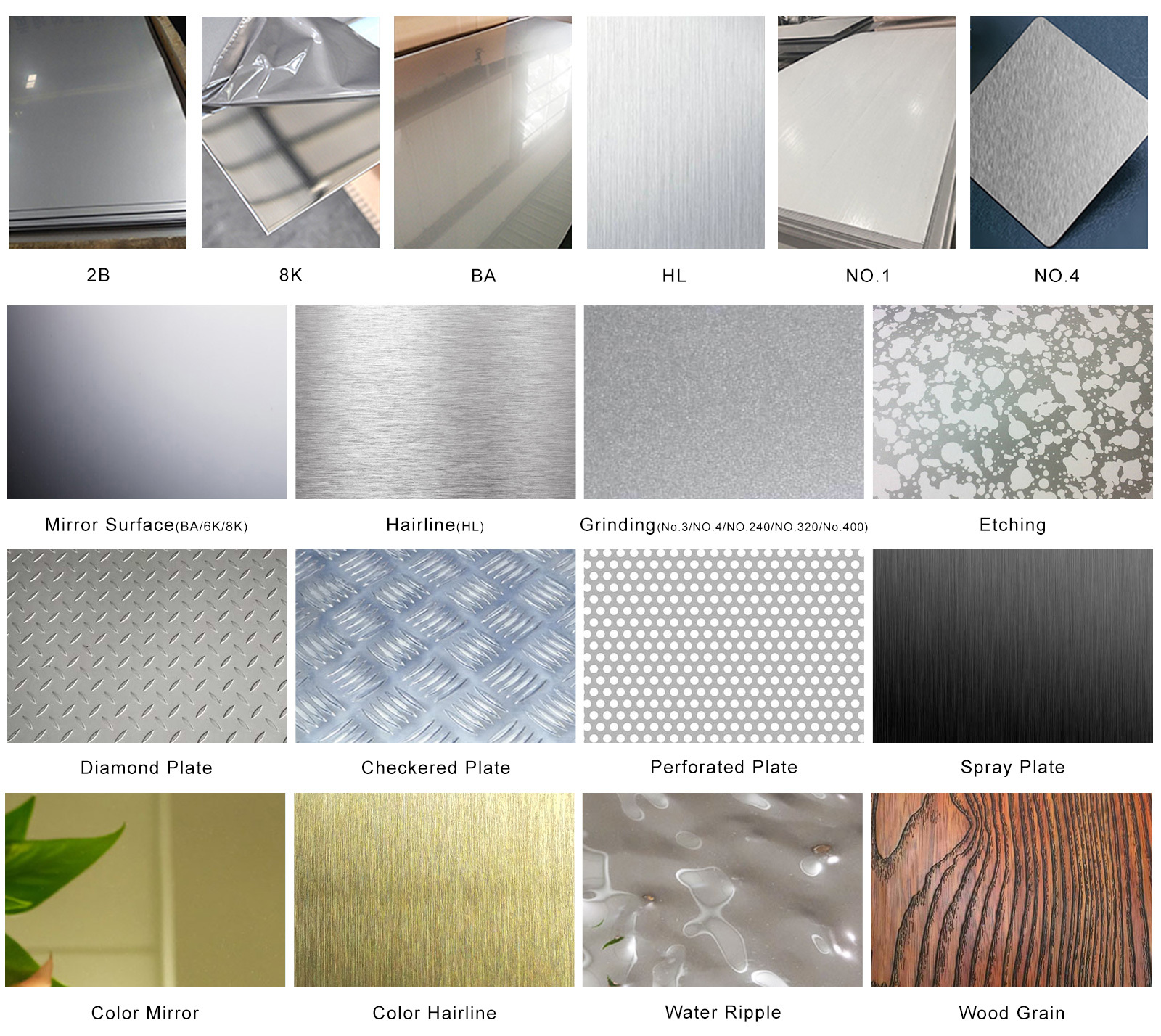

Our Factory

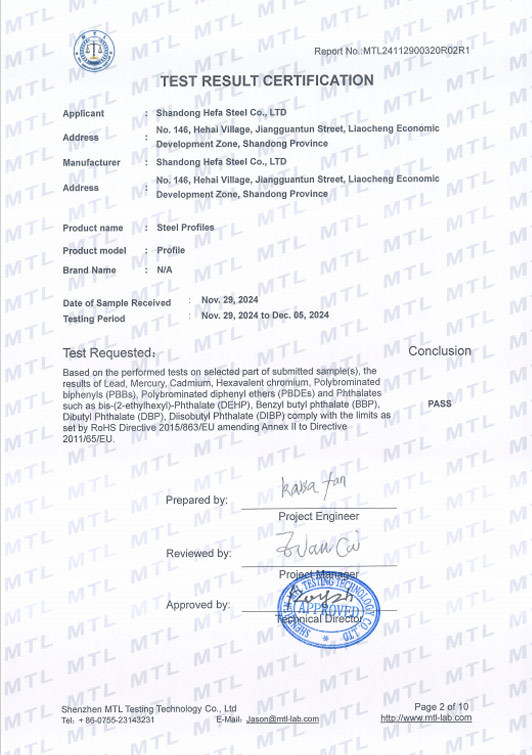

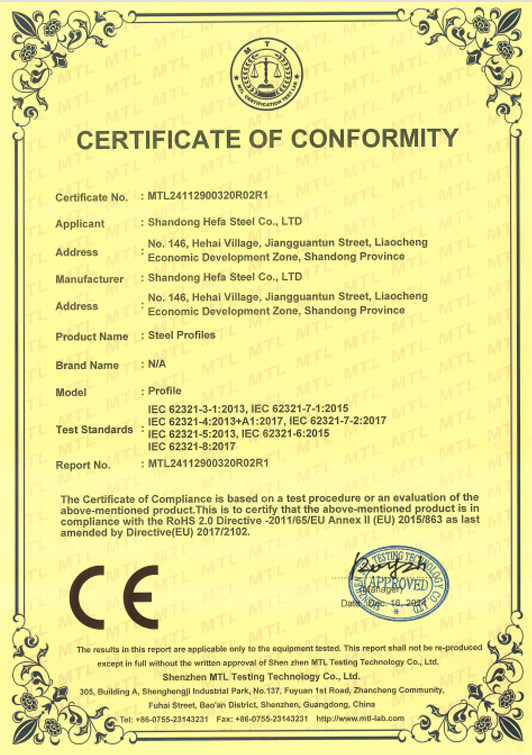

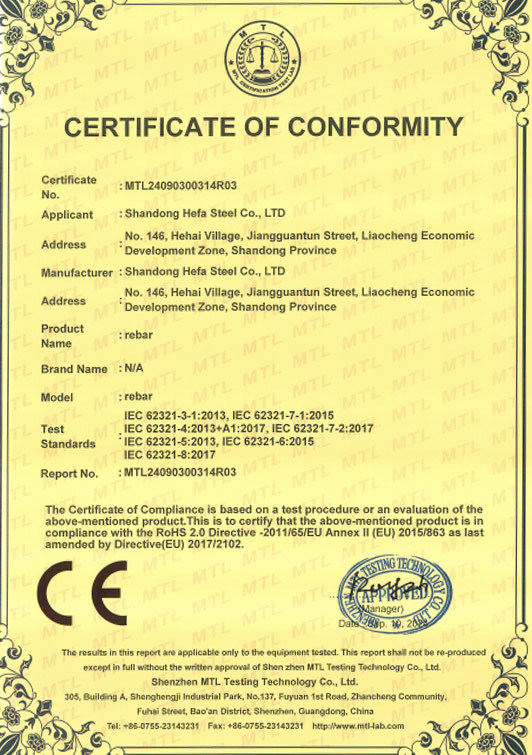

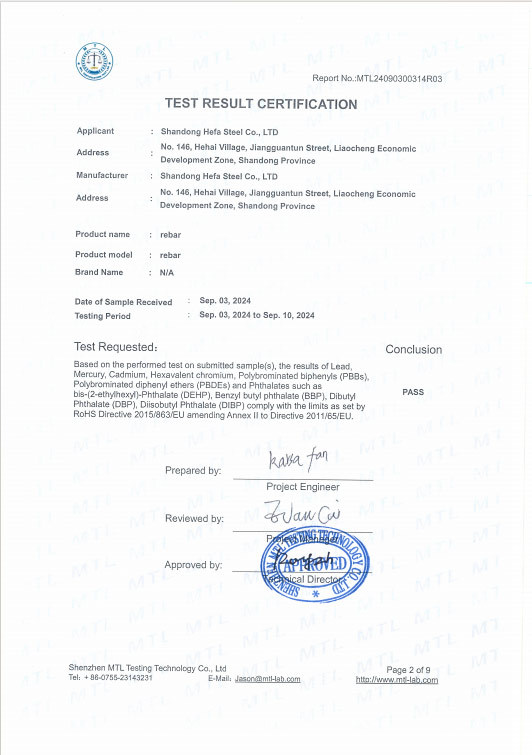

Certification

Unwaveringly prioritizing quality, the company has obtained ISO9001 international quality management system certification and has subsequently received eight other prestigious certifications, including the Enterprise Credit Rating Certificate, the Quality and Service Reputation Certificate, and the Integrity Demonstration Unit designation, establishing a comprehensive quality assurance system.

Exhibition

We are committed to providing customers with high-standard, multi-specification steel products, including coils, plates, profiles, pipes, and wire rods. These products strictly comply with various international and domestic standards, including GB, ASTM, JIS, and DIN, meeting the diverse needs of customers in different regions.

Frequently Asked Questions

— How long does your delivery time take?

Generally, our delivery time is within 7-45 days, if there is a great demand or special circumstances, it may be delayed.

— How could you guarantee your products?

Each piece of products is manufactured by certified workshops, inspected by Linxu piece by piece according to national QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

— Do you accept the third party inspection?

Yes absolutely we accept.

— Do you provide samples ? Is it free or extra ?

The sample could can provide for customer with free,but the courier freight will be covered by customer account.

— Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

— Are you trading company or manufacturer ?

We are professional manufacturer with rich experience, and our company also is a very professional a trade company for steel products. We can also provide a wide range of steel products.

GET A FREE QUOTE

RELATED PRODUCTS