PRODUCTS

DX51D Z150 Galvanized Sheet

Category:

Galvanized Steel Sheet

keywords :

Galvanized Steel Sheet

Product Introduction

DX51D Z150 Galvanized Sheet Description

The Z150 in the DX51D Z150 galvanized steel coil is the actual coating name. The manufacturer describes the DX51D Z150 material as a mild steel galvanized layer for steel products. Specifically, DX51D is a steel grade characterized by its cold-formed bending and profiling qualities. The steel grade corresponds to steel grade 1.0917

Scope of Application

Galvanizing products are widely used in industry, agriculture, animal husbandry and fishery, energy, transportation, chemical industry, light industry, home appliances, construction, communications, national defense and other fields.

Product Parameters

|

Product Name |

DX51D Z150 Galvanized Sheet |

|

Thickness |

0.12mm-6.00mm |

|

Width |

600mm-1500mm |

|

Length |

1m-12m, Support Customization |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

|

Zinc Layer |

Hot Galvanizing: 60-275g/m² |

|

Pre-galvanized: 80-275g/m² |

Chemical Composition

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ti |

|

Forcold Forming Chinese Standard |

DX51D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

DX52D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX53D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX54D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX56D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX57D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

Forcold Forming Japanese Standard |

SGCC |

0.15 |

0.50 |

0.80 |

0.050 |

0.030 |

0.025 |

|

SGCD1 |

0.12 |

0.50 |

0.60 |

0.040 |

0.030 |

0.025 |

|

|

SGCD3 |

0.08 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

SGCD4 |

0.06 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

For Structure Japanese Standard |

SGC340 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.025 |

|

SGC400 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.150 |

|

|

SGC490 |

0.30 |

0.50 |

2.00 |

0.200 |

0.035 |

0.025 |

|

|

SGC510 |

0.30 |

0.50 |

2.50 |

0.200 |

0.035 |

0.025 |

|

|

For Structure AISI Standard |

S220GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

S250GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S280GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S320GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S350GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

|

|

S550GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

Mechanical Properties

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD Z/ZM/AM |

220 |

300 |

20 |

|

S250GD Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD Z/ZM/AM |

280 |

360 |

18 |

|

S300GD A/AM |

300 |

380 |

18 |

|

S320GD Z/ZM/AM |

320 |

390 |

17 |

|

S350GD Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD A/AM |

450 |

480 |

15 |

|

S550GD Z/ZM/AZ/AM |

550 |

550 |

- |

Galvanized Surface Selection

|

Zero Spangle |

Minimized Spangle |

Normal Spangle |

Large Spangle |

|

|

|

|

|

|

Use of The Environment |

Recommended Zinc Thickness |

|

Indoor Use |

Z10 or Z12 (100g/㎡or 120g/㎡) |

|

Suburbs |

Z20 and Painting (200g/㎡) |

|

Urban or Industrial Area |

Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Coastal Area |

Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Punch or Deep Drawing Application |

Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

|

Surface Treatment Type |

Code |

Features |

|

Chromic Acid Treatment |

C |

Good corrosion resistance, suitable for bare state |

|

Chromic Acid Treatment+Oiling |

S |

Good corrosion resistance |

|

Phosphoric Acid Treatment (Including Sealing Treatment) |

P |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling |

Q |

Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment) |

T |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling |

V |

Has a certain corrosion resistance, good paint performance, and prevent rust |

|

Oiling |

O |

Prevent rust during transportation and storage |

|

No Treatment |

M |

Suitable for immediate painting |

Material Comparison

|

Chinese Standard |

Japan Standard |

European Standard |

|

DX51D Z/DC51D Z (CR) |

SGCC |

DX51D Z |

|

DX52D Z/DC52D Z |

SGCD1 |

DX52D With |

|

DX53D Z/DC53D Z/DX54D Z/DC54D Z |

SGCD2/SGCD3 |

DX53D Z/DX54D Z |

|

S220/250/280/320/350/550GD Z |

SGC340/400/440/490/570 |

S220/250/280/320/350GD Z |

|

DX51D Z/DD51D Z (HR) |

SGHC |

DX51D Z |

Packing and delivery

The products have been exported to more than 100 countries and regions, including Turkey, Russia, Saudi Arabia, UAE, Iran, Kuwait, Poland, Philippines, Indonesia, Kazakhstan, Brazil, Mexico, Egypt, Nigeria, South Africa, Australia, etc.

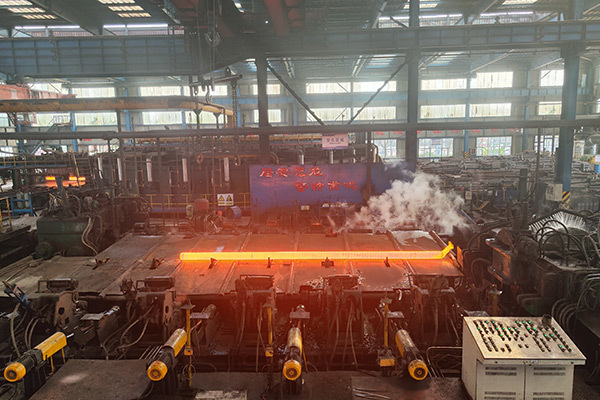

Our Factory

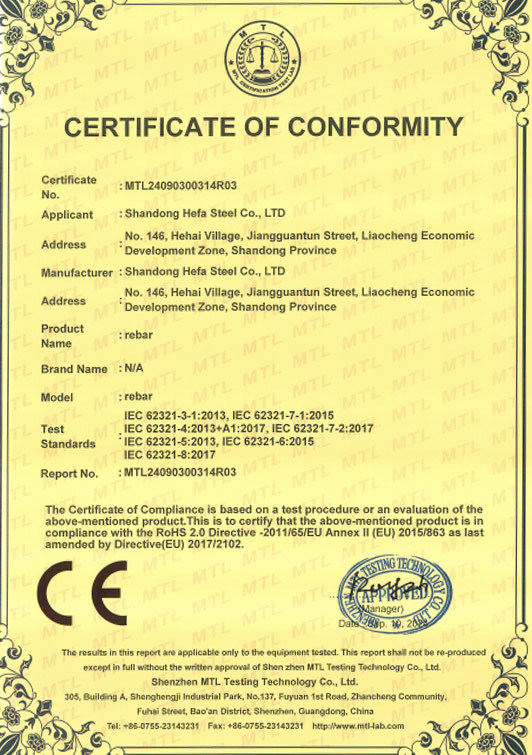

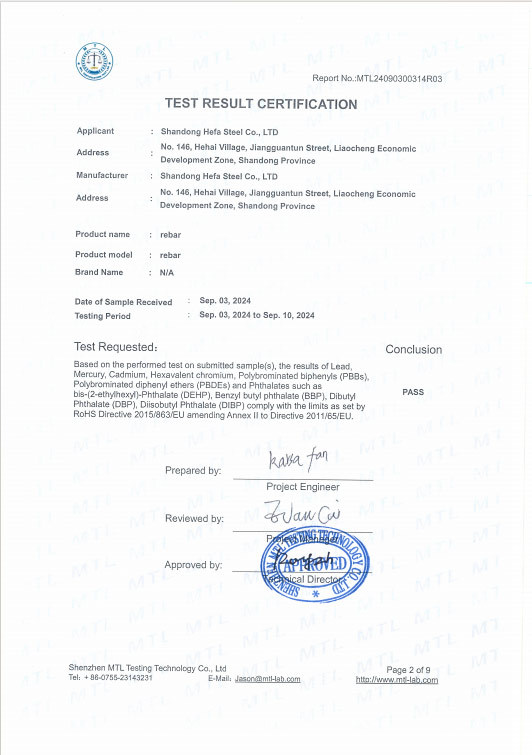

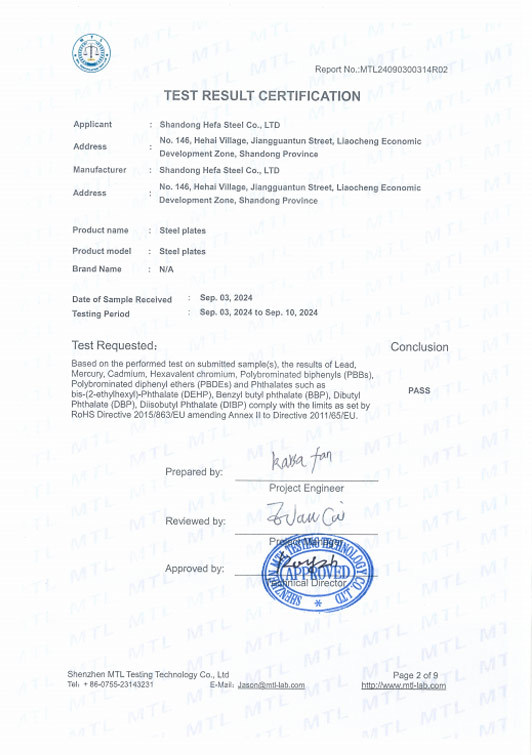

Certification

The company has passed ISO9001 international quality management system certification and has obtained 8 quality system certifications, including enterprise credit certificate, quality service certificate, and integrity management demonstration unit.

Exhibition

Main products: coils, sheets, profiles, pipes, wires, etc. Can comply with standards such as GB, ASTM, JIS, DIN, etc. The company has established long-term cooperative relationships with well-known domestic steel mills.

The company currently has over 50000 tons of inventory, with multiple varieties for you to choose from!

Frequently Asked Questions

— How long does your delivery time take?

Generally, our delivery time is within 7-45 days, if there is a great demand or special circumstances, it may be delayed.

— How could you guarantee your products?

Each piece of products is manufactured by certified workshops, inspected by Linxu piece by piece according to national QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

— Do you accept the third party inspection?

Yes absolutely we accept.

— Do you provide samples ? Is it free or extra ?

The sample could can provide for customer with free,but the courier freight will be covered by customer account.

— Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

— Are you trading company or manufacturer ?

We are professional manufacturer with rich experience, and our company also is a very professional a trade company for steel products. We can also provide a wide range of steel products.

GET A FREE QUOTE

RELATED PRODUCTS